Leave Your Message

In recent years, the demand for Truck Work Lights has surged, driven by the growing need for enhanced visibility in various work environments. A report by MarketsandMarkets predicts a market growth rate of 5.6% for work lights by 2026. This rise underscores the critical role that effective lighting plays in increasing safety and productivity. Industry expert John Stevens states, “Investing in quality Truck Work Lights is essential for any professional who works after dark.”

LED technology has revolutionized Truck Work Lights, offering brighter illumination and longer lifespans. These lights can withstand harsh weather conditions, making them reliable on job sites. However, not all options provide the same benefits. Some cheaper alternatives may fall short on performance and durability. Reflecting on this, it’s crucial to consider not just initial costs but long-term value. Poor lighting can lead to accidents and inefficiencies, ultimately costing more than quality options in the long run.

As the market evolves, staying ahead of trends is vital. Understanding the features of Truck Work Lights can help users make informed decisions. This insight ensures they select products tailored to their specific needs, ultimately enhancing safety and efficiency in the workplace.

When considering the top features of truck work lights for 2026, brightness is key. A powerful light output improves visibility in challenging conditions. High-lumen LED options shine brightly, illuminating dark work areas. Additionally, color temperature matters. A cool white light can enhance visibility more than a warmer hue.

Durability is another critical feature. Work lights should withstand harsh environments. Many models come with rugged housings. They resist water and dust, ensuring long-lasting performance. It's important to think about battery life too. Longer-lasting batteries reduce the need for frequent replacements.

Versatility in mounting options offers more flexibility. Some lights can be mounted on the truck, while others are portable. This adaptability caters to various work scenarios. Adjustable beams can focus light where it's needed most. However, not all features may suit everyone's needs. Personal preferences and specific tasks can influence final choices. Consider how these features align with your work habits before deciding.

| Feature | Description | Benefits |

|---|---|---|

| LED Technology | Energy-efficient lighting with long lifespan. | Reduces energy costs and requires less frequent replacements. |

| Adjustable Mounting Options | Flexible installation angles for versatile lighting. | Improves visibility in hard-to-reach areas. |

| Waterproof Rating | Sealed against water and dust ingress. | Ensures reliable performance in all weather conditions. |

| High Lumen Output | Bright illumination for enhanced visibility. | Increases safety during nighttime or low-light work. |

| Durable Construction | Constructed with high-quality materials. | Provides long-lasting reliability and withstands tough conditions. |

| Magnetic Base | Easily attachable to metal surfaces. | Facilitates quick setup and changes in positioning. |

In truck work environments, enhanced visibility is crucial. Bright and focused lights allow workers to see their surroundings clearly. This is especially important at night or in low-light conditions. A well-lit workspace reduces the chances of accidents. It also boosts overall safety for workers and equipment. When visibility improves, tasks can be performed more efficiently.

Moreover, good truck work lights assist in detailed inspections and repairs. A truck engine or framework can have hidden issues that need attention. Adequate lighting can reveal these flaws quicker. Workers can diagnose problems effectively, reducing downtime. Real-time visibility also aids in precise maneuvering during loading or unloading tasks.

However, not all lights provide the same level of illumination. Some may create shadows or distort colors. This can lead to misjudgments. It's essential to evaluate lighting options thoroughly. Workers should choose lights that provide even brightness without glare. Regularly checking light functionality is important too. Working under subpar lighting can affect productivity.

When looking for truck work lights, durability and weather resistance are paramount. Workers often face harsh conditions. In fact, studies show that nearly 70% of outdoor jobs occur in inclement weather. This makes reliable lighting a necessity. Modern truck work lights are designed to withstand heavy rain, snow, and extreme temperatures. They often feature robust housing materials, such as aluminum or high-grade plastics.

Many products now have IP ratings that indicate their resistance to water and dust. For example, lights with an IP68 rating can be submerged in water without damage. This is crucial for workers who may operate in muddy or wet environments. In contrast, lights that lack proper sealing can easily fail, leaving workers in the dark. Research indicates that equipment failures can lead to costly downtime.

In terms of lifespan, high-quality truck work lights can last over 50,000 hours. However, not all lights meet this benchmark. It is essential to consider the manufacturing process and material sourcing. Also, consider how the light performs at different temperatures. While many lights function well at moderate temperatures, some may struggle in extreme cold or heat. Always assess the quality of lights for specific job requirements.

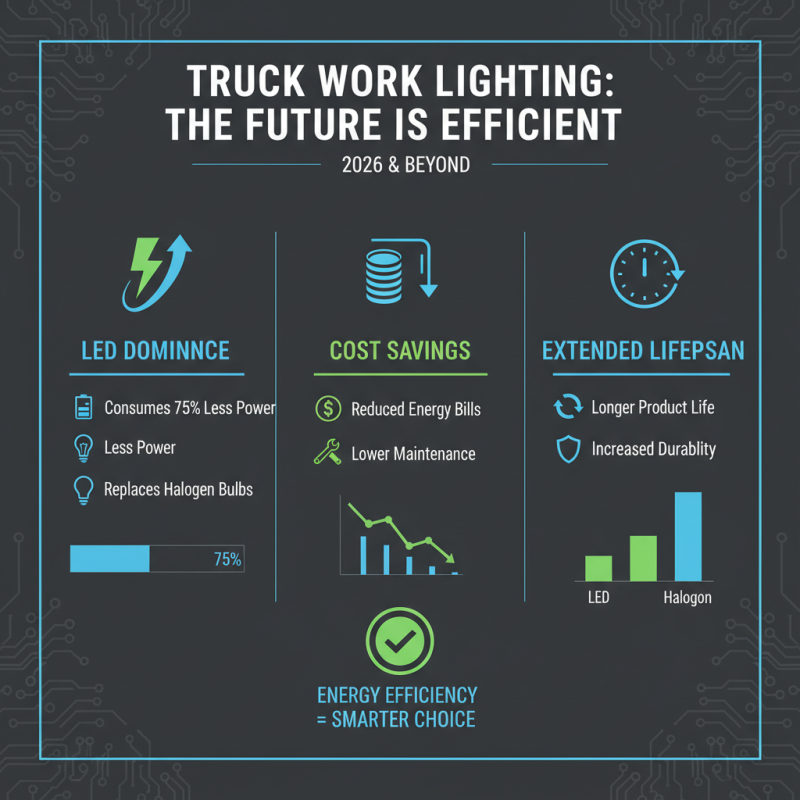

Energy efficiency is a hot topic in the truck work lighting industry as we move toward 2026. Recent reports indicate that LED technology is set to dominate the market, with energy-efficient lights consuming up to 75% less power than traditional halogen bulbs. This shift not only reduces energy costs but also extends the lifespan of lighting, leading to lower maintenance expenses.

Trends in 2026 show a surge in smart lighting systems. These systems adapt to environmental conditions, optimizing energy usage. For instance, lights can adjust brightness based on ambient light or motion detection. This proactive approach can further enhance efficiency, with potential energy savings reaching 40% compared to standard lighting.

Tips: Consider regular maintenance to ensure optimal performance. Dirty lenses can reduce lighting efficiency. Switching to LED systems might require initial investment but offers long-term savings. Make informed choices that balance upfront costs with future benefits.

When choosing work lights for trucks, LED options often stand out. These lights are known for their brightness and energy efficiency. LEDs consume less power compared to traditional lights. They last much longer, reducing replacement costs. This longevity means fewer interruptions during work.

However, traditional lights still hold appeal for some users. They offer a warmer light that many find comforting. Some may argue that they are easier to repair and replace. Yet, traditional lights tend to consume more energy and generate more heat. This can lead to burnout and safety risks.

It’s crucial to weigh the pros and cons. LED lights shine brightly, but their cost can be higher initially. Traditional lights might feel familiar, but their limitations are significant. Users must consider which features matter most in their work environment.